As precious metals become more and more difficult to mine with large deposits being largely exhausted via traditional mining methods, every gram of metal needs to be recovered. Let BADGERCHROME Mixed Metal Oxide anodes help you leave nothing behind.

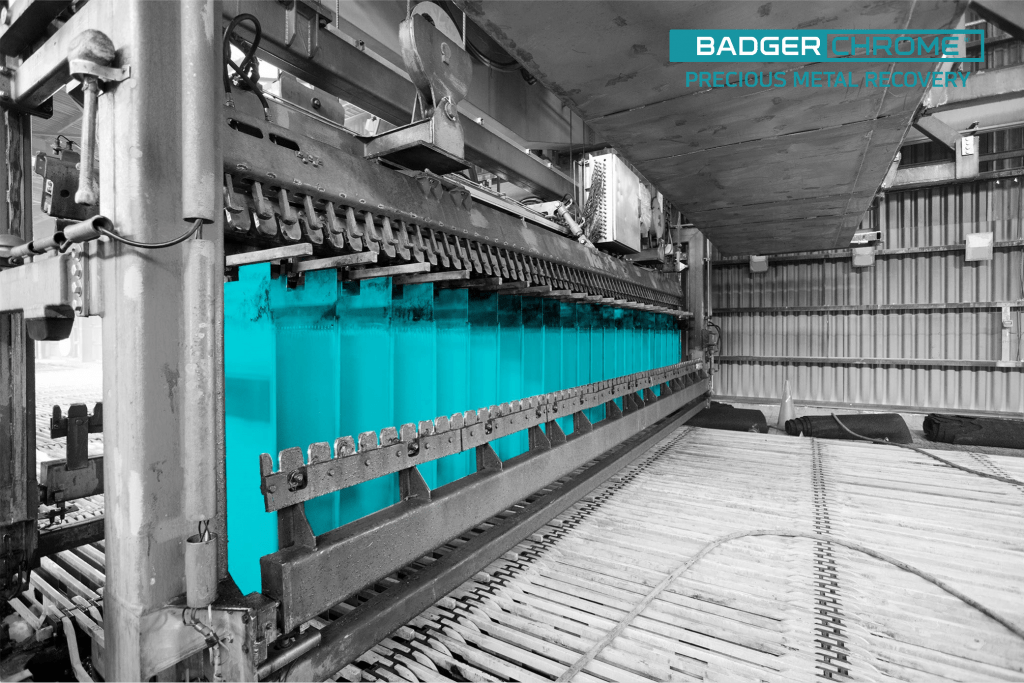

Electrowinning or electroextraction is a purification process that puts a metal ore into a solution and using electrodeposition to remove the pure metal from the solution – what is commonly known as leaching. This is a very economical process for purification of non-ferrous metals. The historical anode of choice for electrowinning is lead dioxide. While this anode type works well enough, the advantages of BADGERCHROME mixed metal oxide (MMO) far outweighs the learning curve for this advanced process. By utilizing BADGERCHROME anodes, you will reduce your energy consumption (and normalize it), reduce lead waste, increase shape options, and reduce environmental pollution. The choice is clear BADGERCHROME anodes will show real changes to your yields both financially and physically.

American Carbon Company has experience designing anodes for electrowinning applications of nickel, zinc, cobalt, and copper as well as precious metals such as gold, silver, platinum metal group metals, and cadmium.

BADGERCHROME anodes are the premier option for all electrorefining and electrorecovery operations. Contact Us today to start designing the perfect anode for your application.

| BADGERCHROME ADVANTAGES |

| Constant voltage through anode life |

| Predictable end product quality |

| Proven lower anodic operating potentials |

| Increased energy savings through uniform current distribution |

| Increased flexibility in shapes and sizes for better yields |

| High mechanical stability |

| High thermal stability |

| No breakdown product buildup |

| Fewer impurities increases yield |

| Custom BADGERCHROME Design Parameters to Consider |

| Base Material: Grade 1 Titanium |

| Coatings: Ruthenium oxide, Iridium, tantalum, platinum, and others as designed |

| Coating Thickness: 0.1 µm to several hundred µm |

| Electrode Shape: Square, rectangle, circle, plate, strip expanded mesh, corrugated, perforated wire, rods, tubes, discs or customized to your exact needs |

| Current Density: 350-500A/m2 |

| Common Applications |

| Non-ferrous metal extraction (copper, zinc, nickel, cobalt) |

| Precious metal extraction (gold, silver, platinum metal group) |

| Precious metal recovery (copper, precious metals, other valuable metals) |